- Available with both fixed and operable panels

- Accept glazing infills from less than 1/4″ to 1″ (6.4 to 25.4)

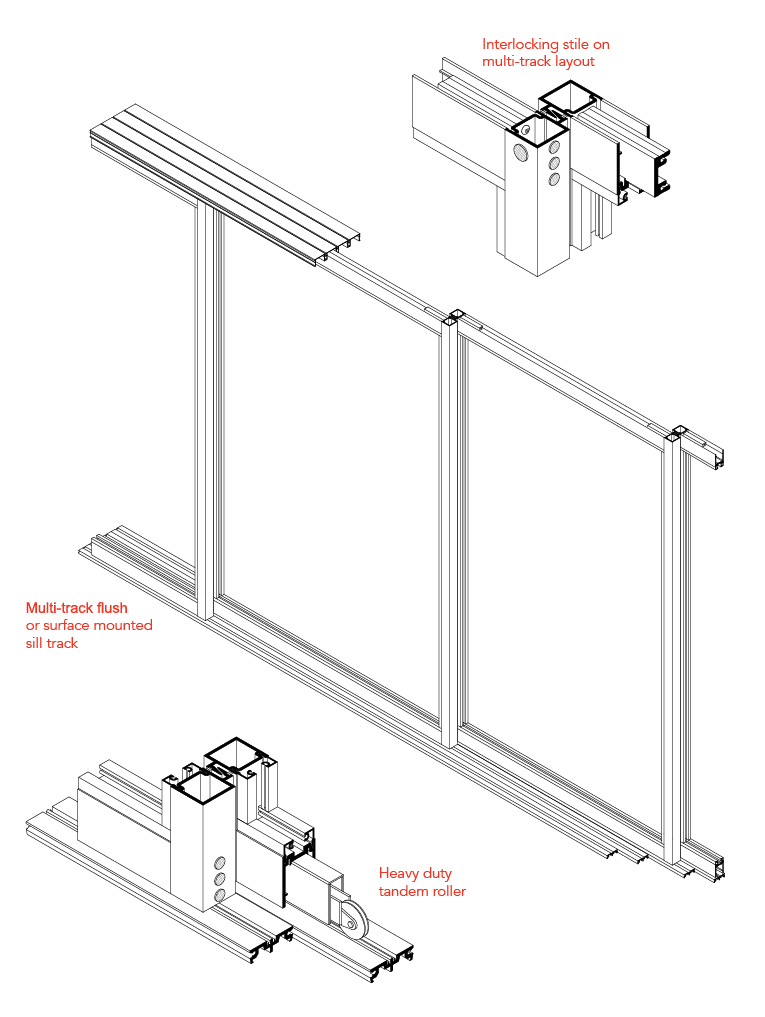

- Interior sliding mall front with parallel stacking capability

- Multi-track or single track with flush or surface mounted tracks

- Stainless steel cap on sill track

- Heavy-duty tandem roller assembly

- Friction-reducing slide buttons at the head of each vertical stile

- Companion fixed lights

- Narrow stile 190 egress doors

- Factory fabricated and shipped knocked down for local assembly

- Structurally glazed with 1/4″ (6.4 mm) glass

Thermal Technology

Find out more here.

1010C Sliding Mall Front - Architectural Detail Manual

1,020 KB

Storefront Framing Product Selection Guide

571 KB

Anodized and Painted Aluminum Extrusions - EPD

765 KB

Finishes Information - Architectural Detail Manual

238 KB

Anodize Finishes - Color Chart

82 KB

Liquid Paint - Color Chart - Permadize®

1 MB

Liquid Paint - Color Chart - Permafluor™

350 KB

1010C Sliding Mall Front - English

Intermediate horizontal at Egress Door

Alternate surface Mounted Track

Flush Jamb - Sliding Panel

While most of our products are not hazardous in and amongst themselves, hazardous properties can develop when the product is altered through cutting, welding, and grinding. Details on the specific hazards that can develop and the proper protective measures to use can be found in the SDSs.

Arconic’s SDS database provides PDF files of safety information on specific materials. The SDS ID numbers (product code) and description for materials used in Kawneer products are listed below.

SDS # DESCRIPTION / TITLE

1405 – Kawneer Thermal Break Filled Extrusions

1385 – Kawneer Acrylic Paints

1386 – Kawneer Fluoropolymer Paints

1526 – Kawneer Bloomsburg Solvent Recovery Still Residuals

1387 – Painted Architectural Aluminum Extrusions

509 – Aluminum Extrusions, Anodized Aluminum Products

Search Arconic’s SDS database for safety information on specific materials.

Project Warranty Cover Sheet (English)

137 KB

Project Warranty Cover Sheet (French-Canadian)

137 KB

Project Warranty Cover Sheet Sample (English)

139 KB

Project Warranty Cover Sheet Sample (French-Canadian)

140 KB

Material & Workmanship - English

185 KB

Material & Workmanship - French

190 KB

Material & Workmanship Sample (English)

203 KB

Material & Workmanship Sample (French Canadian)

212 KB

Anodized Finishes Warranty - English

523 KB

Anodized Finishes Warranty - French

517 KB

Anodized Finishes Sample (English)

529 KB

Anodized Finishes Sample (French Canadian)

524 KB

Painted Finishes Warranty - English

557 KB

Painted Finishes Warranty - French

538 KB

Painted Finishes Sample (English)

565 KB

Painted Finishes Sample (French Canadian)

550 KB

Insulating Glass Warranty - English

498 KB

Insulating Glass Warranty - French

499 KB

Insulating Glass Sample (English)

502 KB

Insulating Glass Sample (French Canadian)

504 KB

Laminated Glass Warranty - English

122 KB

Laminated Glass Warranty - French

123 KB

Laminated Glass Sample (English)

126 KB

Laminated Glass Sample (French Canadian)

128 KB

Corrective Field Repairs (English)

154 KB

Corrective Field Repairs (French-Canadian)

152 KB